BATTMASTER® - Introduction

… helping you to take the right decision

Modern industrial, energy generation and distribution, medical, telecom and transportation systems depend more and more on batteries.

Here are some reasons why:

-

deregulation of the energy production and distribution decreases the quality of grid power supply, making the use of back-

up systems more needed than before -

battery technology is mature

-

today’s power electronics allow extensive battery use for many purposes

-

green power generation (e.g. solar and wind) involves consistent use of batteries

-

Telecom’s huge expansion requests high volume of batteries

For many of the high reliability systems the battery is a critical part.

Batteries have a limited life time and number of charge/ discharge cycles.

They present various fail causes like aging, high environmental temperature, deep discharge, incorrect charging (overvoltage or overcurrent), overload, mechanical stress or just bad quality.

For most of the batteries the change of some parameters can predict a failure. Monitoring of voltage, temperature, internal resistance and current gives precious information about the risk of failure of a battery.

When evaluating a BMS the potential user must consider the following:

-

is the application critical?

-

are the batteries a weak point of the application?

-

If “yes” to 1) and 2) what is the risk/cost of the possible damage caused by a battery failure?

If the estimated cost of the damage is higher than the cost of a BMS, then a BMS must be used.

Remember:

-

DO NOT compare the cost of the batteries with the cost of the BMS! A failure of a relatively cheap battery can create an enormous damage. Always look at the BMS as an insurance against serious troubles.

-

DO NOT avoid a BMS even if you use high reputation batteries. Like any other products batteries can present unexpected problems.

-

DO NOT consider a BMS just as a COST! A BMS may save you money not only by predicting critical failures, but also by avoiding unneeded replacement of good batteries.

-

DO NOT consider a BMS as the DECISION MAKER regarding the replacement of batteries into your system. It is just a USEFUL TOOL in helping you take the right decision. You are the ULTIMATE responsible for your system’s reliability.

BATTMASTER® is based on latest technologies and answers to most of the requirements of a modern BMS.

BATTMASTER® - Overview

As a result of important R&D efforts and constant focus on the market requirements BattMaster® is the first wireless Battery Monitoring System (BMS) that continuously measures and logs the voltage, temperature, internal resistance and current (optional) of lead acid batteries (2V, 6V or 12V nominal voltage) as individual cells / blocks or within a battery string. This easy to use and install system will dramatically improve your systems' reliability and operating cost.

BATTMASTER® -

BATTMASTER® -

|

BattMaster® is composed of: |

|||

|

Quantity |

Component Type |

Description |

|

|

1 |

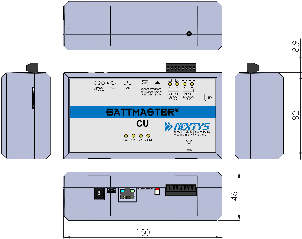

CU (Central Unit) |

Collects the DAM and IDAM data, manages communication with the PC |

|

|

1~1024 |

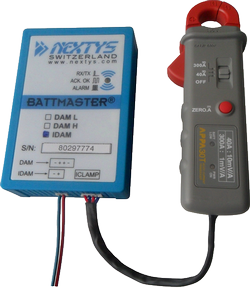

DAM (Data Acquisition Module) |

Measures voltage, temperature and internal resistance of the battery |

|

|

0~64 |

IDAM (Current DAM) Optional |

Measures current of the battery (or string) |

|

|

1 |

PC with BattMaster SW installed Optional |

Displays data and configures the system |

|

Note: the CU supports a total of 1024 DAMs and IDAMs (max. 64 IDAMs).

It can be integrated with any remote supervising system based on LAN, GSM, Internet or other communication means.

ADVANTAGE

-

-

-

-

-

-

-

-

FEATURES & BENEFITS

WIRELESS COMMUNICATION

Battmaster® system consists of individual monitoring devices that are wirelessly connected to the central unit (CU). The communication is in the 868 MHz-

BATTERY DATA LOG

Battmaster® continuously measures and logs battery data including:

-

-

-

-

The raw data sampling rate is high (few ms), the data base refresh rate is user settable (from minutes to hours). All relevant values are recorded; no one can be missed, independently of the set refresh rate.

BATTERY PERFORMANCE COMPARISON

Battmaster® tracks and logs individual battery activity, but displays also the string's parameters (e.g. the string's average voltage or temperature). The end-

ADVANCED USER INTERFACE

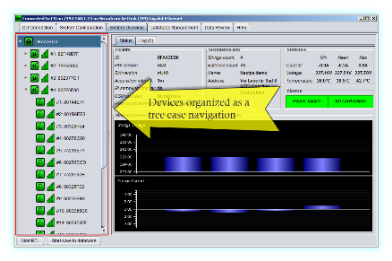

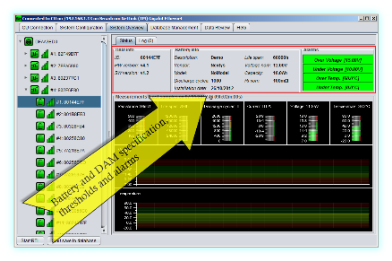

The CU can be interfaced through a USB or a LAN port to a PC that operates the user friendly, features rich Battmaster® application SW (Windows based).

LOW COST / HIGH PERFORMANCE

Battmaster® is a high performance, low cost alternative to existing BMS solutions. It ensures that users are provided with the critical data needed to increase battery system reliability.

BATTMASTER® - Specifications

|

|

|

|

CENTRAL UNIT (CU) |

|

|

DATA ACQUISITION MODULE (DAM) |

|

|

CURRENT DATA ACQUISITION MODULE (IDAM) - |

|

BATTMASTER® - Software

Software Specifications

-

License free (Microsoft Windows XP, 7)

-

Real Time Logging and Monitoring software

-

Keeps all logged data in Microsoft SQL database

-

Battery history review software

-

Allows remote battery supervision via LAN or Internet

-

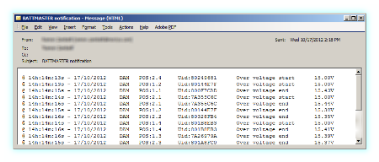

Generates e-

mails and SMS in case of battery alarms (PC required) -

Multiple data exporting possibilities

Intuitive organization of the system elements

Tree ViewBattery specifications and alarm settings

Voltage, temperature, operating time, no. of discharges, alarms and intallation date

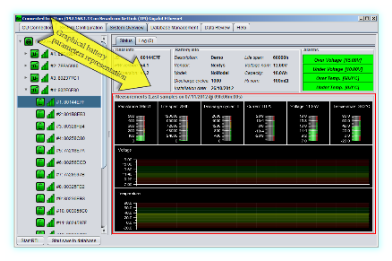

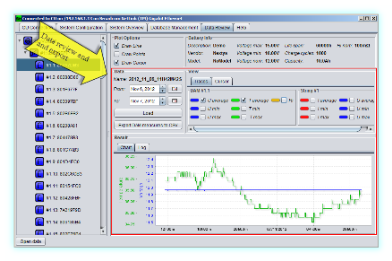

Graphical battery parameters representation

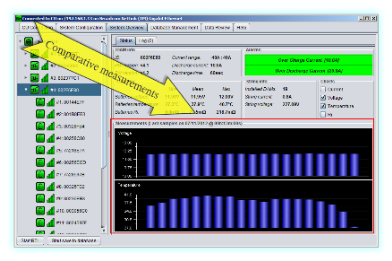

Voltage, temperature, operating time, no. of discharges, alarms, current and measured internal resistanceComparative measurements

Voltage, temperature and Ri can be selected for comparison

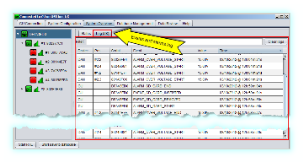

Logs

Events and alarms history screenE-

mails content

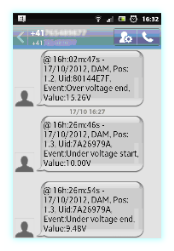

Example

Data history graphical review

Data history graphical reviewSMS content

Example

Current, voltage, temperature and Ri can be selected for review -

-

BATTMASTER® - Photo Gallery

Switzerland, Manno

Evaluation system at The Swiss Center for Scientific Computing

Switzerland, Manno

Detail of final implementation at The Swiss Center for Scientific Computing -396 batteries

Switzerland, Quartino

System installed at NEWAVE (UPS manufacturer)

Switzerland

Evaluation system in a railway control center

Switzerland,

DAMs placed in an APC UPS

Switzerland,

Small UPS battery monitoring